The concept of a global supply chain is a fairly recent one, but it has a long history. Ancient mariners used sailing vessels to bring items to trade with populations in other countries. Rum runners were likely among the first contributors to a fully functioning global supply chain, complete with documentation and records about the product and where it was going, among other data points.

Today, data is critical in supply chain management, tracking millions of items daily to and from nearly every latitude and longitude point on Earth. Modern supply chains simply cannot run without it. This article will look at what supply chain data management is, the benefits, how the data is collected and extrapolated, and other aspects that help organizations at every point of the supply chain keep operations running smoothly.

What is supply chain data management?

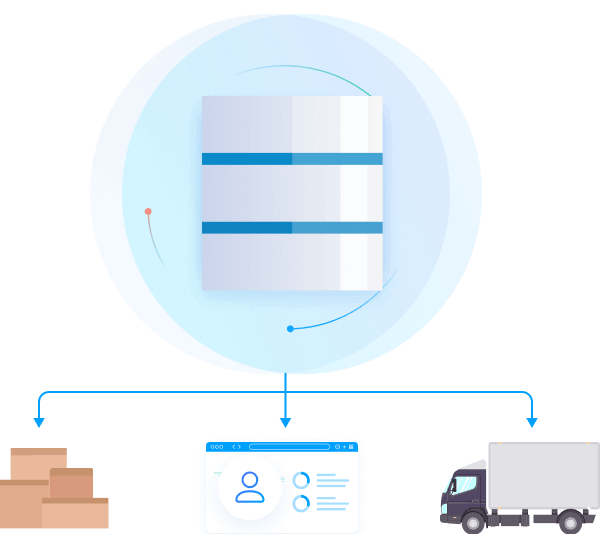

Supply chain data management consists of the collection, analysis, and communication of data throughout the supply chain. The process of managing the data in a supply chain can be likened to managing the supply chain itself. Every point in the supply chain—from the initial sourcing of raw materials to the delivery of finished products to the customer—is driven by and is a result of massive amounts of data.

Like the items that go through a supply chain, the data has a starting and ending point. Data may originate internally and require exchange with external parties, or it may originate with trading partners and require integration into your back-end systems. It also must pass through a lot of points along the way, like MFT & EDI integration platforms, data repositories, and analytics tools. Key components include data collection, integration, transfer, transformation, analysis, and reporting. Processes like demand forecasting, inventory management, logistics, and supplier and customer feedback analysis streamline operations and improve responsiveness.

How is supply chain data collected?

Every point in the supply chain generates data. There are two major ways that the data is sourced:

Primary data collection

This is where data is collected first-hand directly from the source. Primary data collection ensures the information is current, relevant, and specific to the organization. Types of primary data collection include:

- Intracompany processes collect data from within the company’s own operations. Information on production, inventory, order fulfillment, and quality control are used to identify bottlenecks, improve efficiency, plan production cycles, and more.

- Surveys and feedback systems are direct channels through which companies gather customer and supplier data. Customer satisfaction, product quality, supplier performance, and input on delivery times helps companies understand how well it meets expectations and identifies areas for improvement.

- Institutional data pertains to broader, organizational-level metrics. Employee satisfaction, turnover, regulatory compliance, and organizational efficiency provide insights into the overall health of the organization and its capacity to support more efficient operations.

Secondary data extrapolation

This is data collected and authenticated by third parties. It’s useful for understanding competitors, evaluating against industry benchmarks, understanding changes in the market, and other critical insights that help an organization make strategic decisions. They include:

- Data aggregators collect and compile data from various sources into a single comprehensive database. Organizations use aggregators to compare their operations against industry standards, identify trends, and find opportunities that internal data can’t show.

- External data streams are continuous data flows from supply chain partners, market research firms, and government entities. Information on global economic indicators, changes in regulations, logistical obstacles, and more can help an organization stay abreast of conditions that can impact the supply chain.

- Software applications like customer relationship management (CRM) systems, financial and accounting tools, and logistics platforms contain valuable data that can be analyzed for insights that inform demand forecasting, customer trends, and spending.

- Web-sourced data includes industry reports, news articles, social media, and online forums. This information can be analyzed to understand high-level market trends, consumer behavior, and global events that might affect the supply chain.

6 steps of supply chain data management

Good supply chain management is a result of good supply chain data management. Both involve a series of steps to achieve the desired outcome: a seamless flow of goods, information, and value from beginning to end. Here's a breakdown of typical steps:

- Data collection

Information from every stage of the supply chain is collected, including supplier details, production data, inventory levels, shipping information, and customer feedback. The goal is to create a comprehensive dataset that reflects the full scope of the supply chain operations.

- Data analysis

This step involves using statistical tools, machine learning algorithms, or other analytical methods to identify patterns, trends, and anomalies within the data. Data analysis helps make informed decisions, forecast future demand, optimize inventory levels, and identify areas for improvement within the supply chain.

- Data sharing

Exchanging information between all stakeholders, including suppliers, manufacturers, logistics providers, and retailers, is critical for effective supply chain management. Cloud-based platforms, electronic data interchange (EDI) systems, and other collaborative tools help to optimize operations and keep everyone informed.

- Data visualization

Converting complex data sets into graphical representations, such as charts, graphs, and dashboards make it easier for stakeholders to understand data, identify trends, and identify key insights at a glance. Data visualization is crucial for communicating findings, reporting on performance metrics, and supporting strategic discussions within and across organizations.

- Data security and compliance

Ensuring the integrity, confidentiality, and availability of data is critical to the efficient operation of the supply chain. Implementing security measures protects data from unauthorized access and breaches and enables compliance with relevant data protection regulations and industry standards.

- Continuous improvement

Supply chain data management is not a one-time effort but a continuous process. Regularly reviewing and refining data management practices, incorporating new technologies, and adapting to changes improve efficiency, competitiveness, and resilience in the supply chain.

7 benefits of data analytics in supply chain management

Data analytics plays a crucial role in efficient and effective supply chains. Leveraging all the data available enables companies to streamline their operations and gain strategic insights that lead to more accurate decision-making. A few benefits include:

- Enhance supplier and customer relationships

By streamlining data exchange between trading partners, companies can ensure collaborative optimization of inventory levels, order status, shipping updates, and fulfillment confirmation. Effective interchange with critical business partners helps maximize transparency and trust.

- Forecast demand

Data analytics gives organizations a view of historical sales information, market trends, and customer behavior patterns to predict potential increases or decreases in demand.

- Get real-time visibility into supply chain operations

Integrating IoT (Internet of Things) devices and cloud-based platforms enables companies to monitor supply chain operations in real time to minimize disruption and maintain the flow of operations.

- Monitor logistics KPIs

Data collected from various points in the supply chain, including delivery times, transportation costs, and order accuracy, can be used to gauge performance against key performance indicators (KPIs).

- Optimize transportation routes

Analyzing traffic patterns, weather conditions, and other metrics enables organizations to find the most efficient shipping routes, reducing fuel consumption, improving operational efficiency, and mitigating carbon emissions.

- Manage supply chain risks

Effective risk management ensures the continuity of supply chain operations, even when facing unforeseen disruptions like supplier reliability, geopolitical factors, and market volatility.

- Improve product quality

Data from quality control processes, customer feedback, and returns can be analyzed to identify areas for improvement or product quality trends.

How CData Arc allows you to improve supply chain collaboration

CData Arc boosts collaboration within your supply chain by harnessing the power of standards-based B2B integration solutions to automate communications throughout your supply chain network. Its robust integration capabilities connect disparate systems, applications, and EDI platforms—no matter where they are—ensuring that critical data flows smoothly and securely from one end of the supply chain to the other. Arc helps ensure your supply chain partners' relationships are smooth, transparent, and secure.

Find out for yourself how CData Arc can streamline your supply chain data management with a free trial today.

Try CData Arc today

Get a free 30-day trial of CData Arc to begin automating your B2B integration processes today.